Laser Cutting Machines

How to Laser Cut Acrylic: The Complete Guide

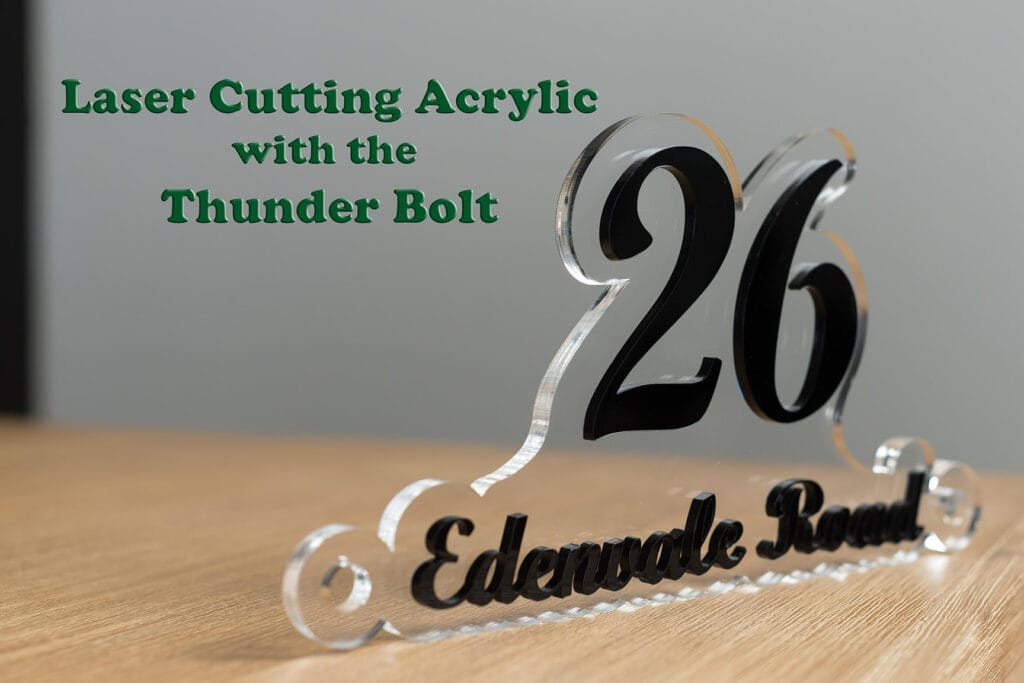

Laser cutting is a precise process of cutting material using a powerful laser beam that melts, burns, or evaporates. This process helps create customised patterns and designs that add significant personalisation to various materials.

As a result, acrylic is becoming an increasingly popular material for laser cutting. Its shiny appearance, transparency, optical clarity, and beautiful colours are the reasons. These attributes make it an ideal material for creating signs, jewellery, displays, and more. Moreover, laser cut acrylic is smooth and creates precise designs for various applications.

You may need a laser cut acrylic machine for commercial needs, practising hobbies or other purposes. Whatever the reason is, you must know how to laser cut acrylic. So, please keep reading to learn its working and helpful laser cutting acrylic tips.

Why you need to know how to laser cut acrylic

An acrylic laser cutting machine is wonderful equipment for initiating fast and precise cutting. However, before trying acrylic laser cutting, you must know some things. Acrylic is a type of plastic, and acrylics are attracted to fire and can produce harmful fumes.

Also, there are various acrylics; for example, Cast acrylic is made of liquid acrylic poured into moulds. The engraved result is a frosted white look and laser cutting created a polished edge. However, it has a high thickness tolerance and a relatively slow production process.

On the other hand, there’s Extruded Acrylic produced from high-volume production methods. It has a low cost, but there are fewer colours. The result of laser engraving is dull and also has a polished edge when laser cut.

So, you have to keep in mind both the materials, their properties, and safety precautions before practising laser cutting acrylic.

Guide to performing acrylic Laser cutting

Here is a complete guide to how to laser cut acrylic:

STEP 1: Create the design for laser cutting

To begin with, choose the design of your choice and use software like CorelDraw & Adobe Illustrator etc., to add, create, and adjust the design on the computer.

This design can be in vector files with formats like SVG, EPS, PDF, DXF, DWG, CDR (CorelDRAW), AI (Adobe Illustrator) etc. In addition, typical drivers transform an image from a computer into a format that the laser cutter can read, which need to be exported into the laser machine software such as LightBurn & RD Works ect.

STEP 2: Adjust the material

Adjust, position the acrylic sheet on the laser bed and adjust as necessary. After uploading your design file to the laser machine, use the framing function to ensure the entire design fits within the material’s boundaries. For optimal results, use a blade table for laser cutting to avoid refractions that can chip the acrylic’s edges. If a honeycomb table is your only option, consider elevating the acrylic with spacers to minimize contact with the honeycomb, or meticulously adjust the laser settings to reduce chipping at the edges.

STEP 3: Adjust the settings

Connect the laser cutting machine to the power and switch it on. Before processing, adjust some settings:

Power: Select the beam’s power, which can be from 0 to 100%. It can vary according to the thickness of the material & the strength of the laser tube fitted inside the machine.

Speed: It’s the speed at which the beam moves by the designs. For thinner materials, speed can be increased. However to get the best polished result it is advise to have the speed at around 10mm/s.

Focus: You can use the laser machines auto focus to get the correct laser head height. If there is no auto focus function then you will need to manually focus.

Air Assist: If your air assist is attached to the side of the laser head, you can cut acrylic and still achieve a polished edge. However, if the air assist is designed to blow directly through the laser head in your machine, it may cause the edges to appear smudged and unpolished.

STEP 4: It’s time to cut

After achieving the desired laser cutting acrylic settings, it’s time to cut. Always go for test cuts and save the settings for future use. Within minutes, you will notice clean and precise acrylic cuts.

Laser cutting acrylic tips

- Select the appropriate acrylic material. Extruded acrylic is ideal for projects that involve only laser cutting and not engraving, as it is more cost-effective. However, keep in mind that extruded acrylic does not yield the best results when engraved.

- Ensure good ventilation for fumes to settle down

- Lower power and slow cutting speed will ensure flawless polished cutting edge for acrylics, I would suggest a cutting speed of 10mm/s.

- Always ensure a safe working environment with proper safety gears. Always keep children away from the working area.

- Clean the acrylic sheet with a non-abrasive cloth, microfibre or lint-free anti-static fabric. Also, don’t put too much pressure on the sheet.

Although the initial cost of a laser cutting machine can be high, its durability and precision cover it. The acrylic laser cutting ensures high quality, maximum cuts in minimum time, versatility and longevity.

This was a detailed guide about how to laser cut acrylic. The easy process and cutting on various materials make it very useful for customisation, commercial needs, and hobbyists.