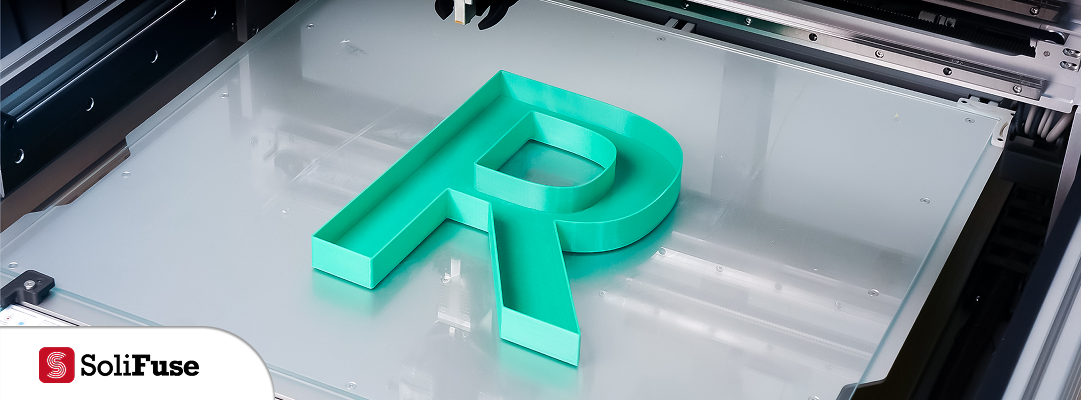

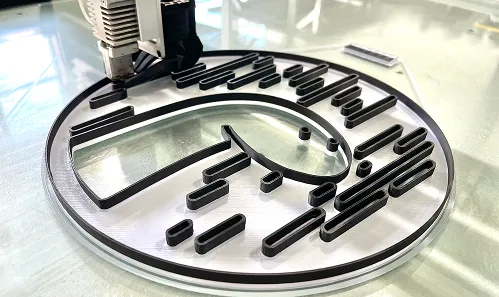

3D Printer for Signage in South Africa

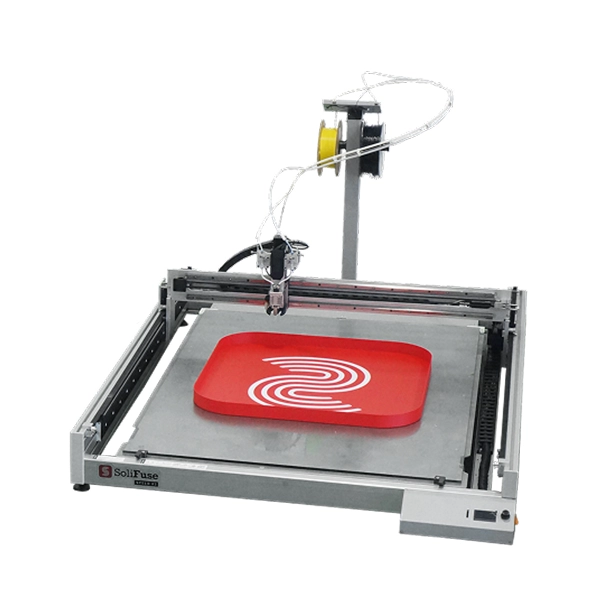

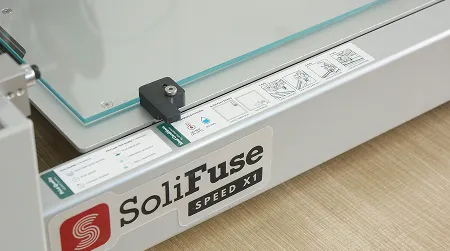

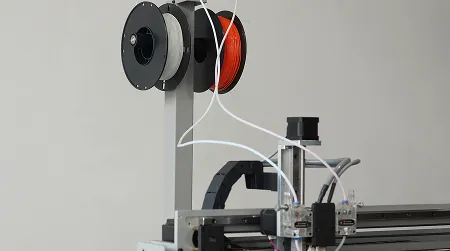

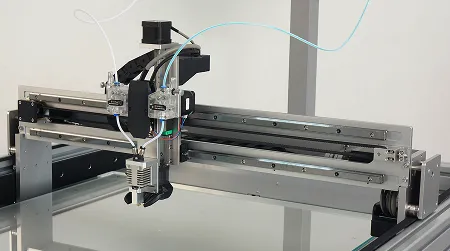

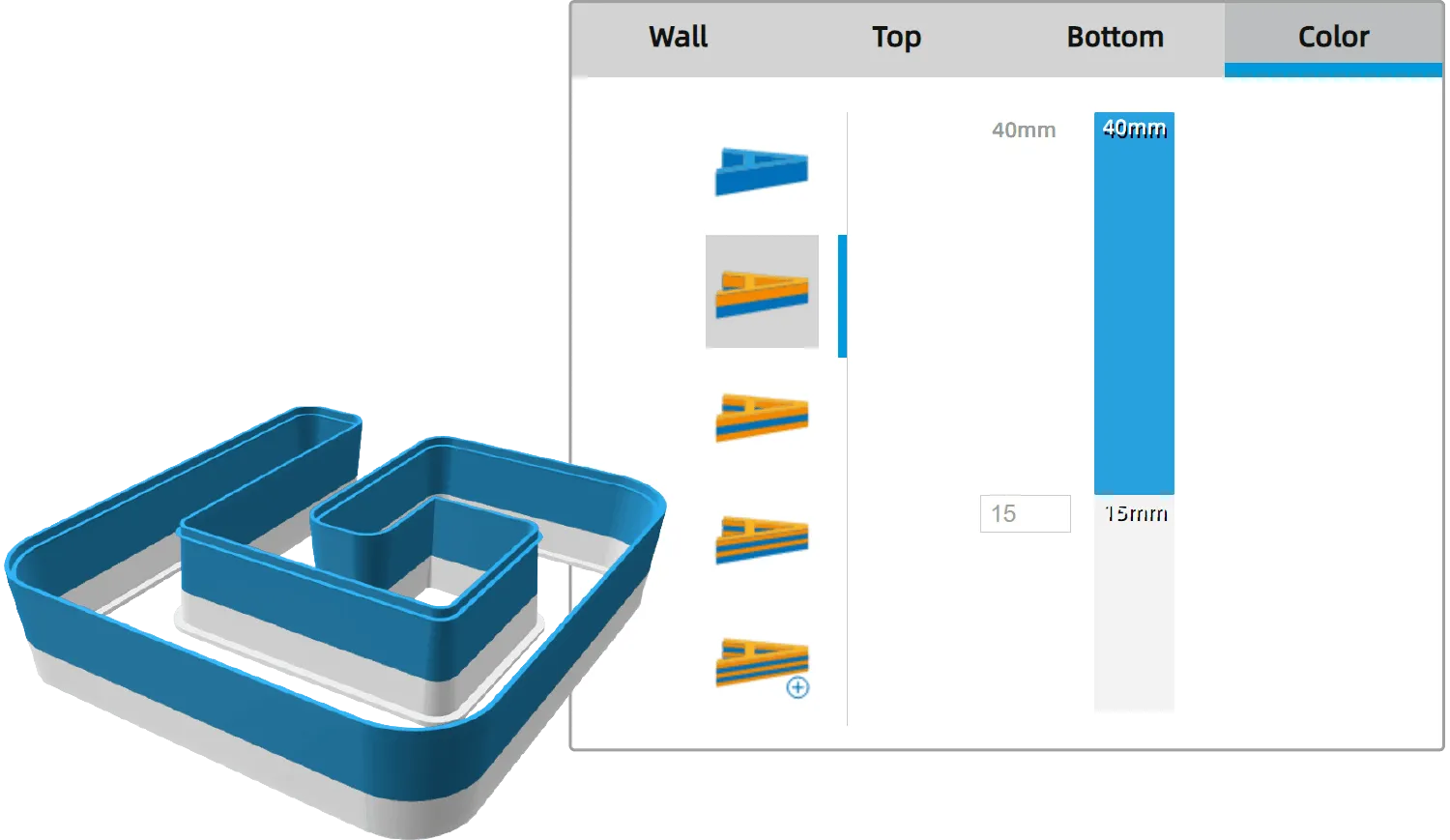

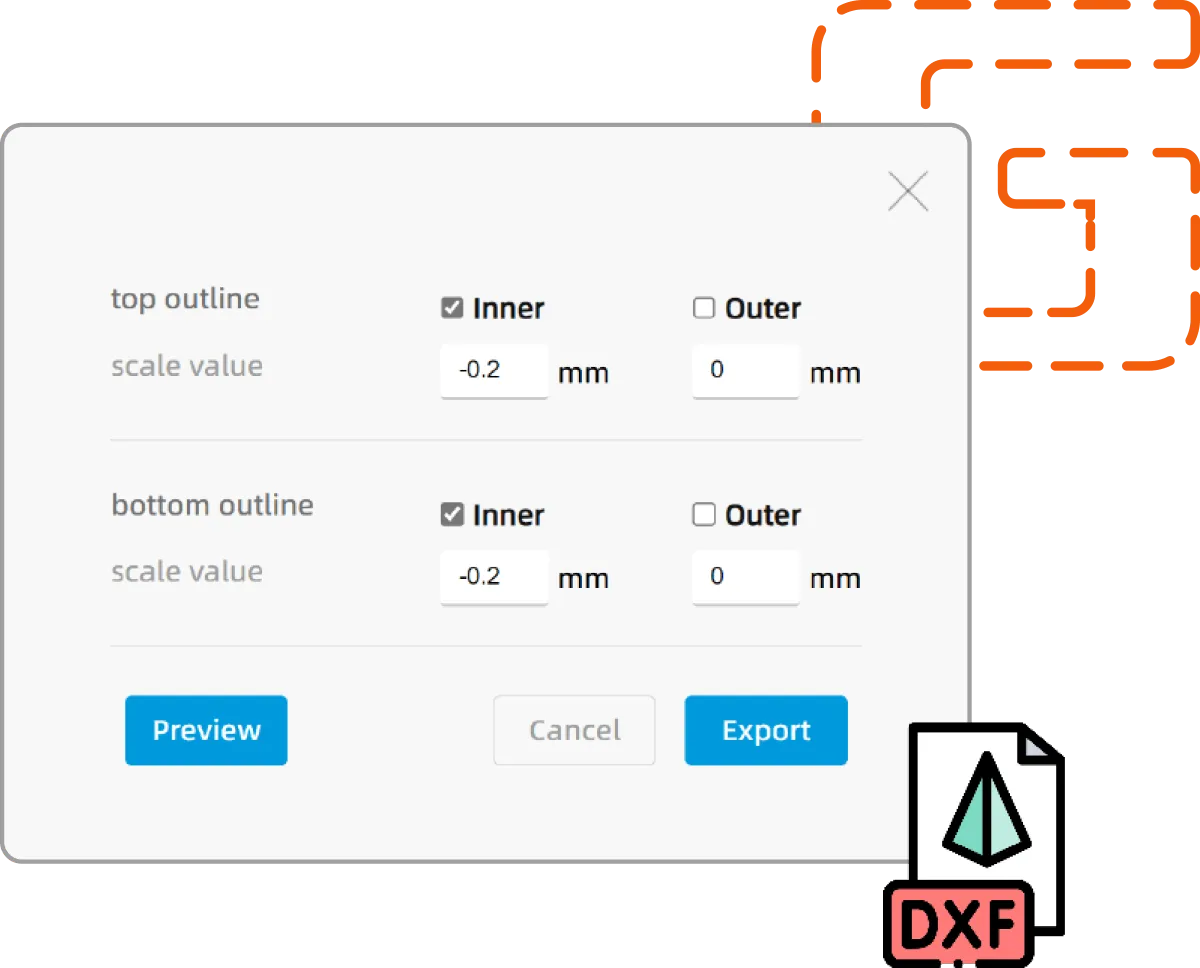

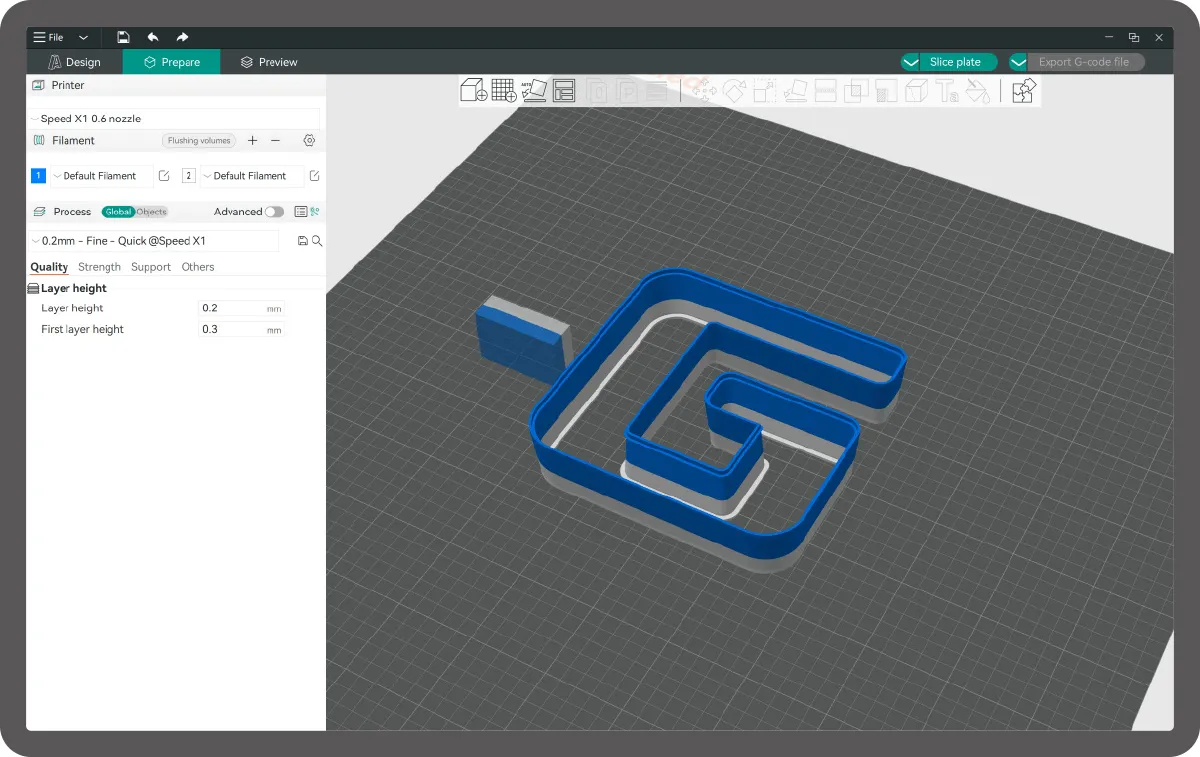

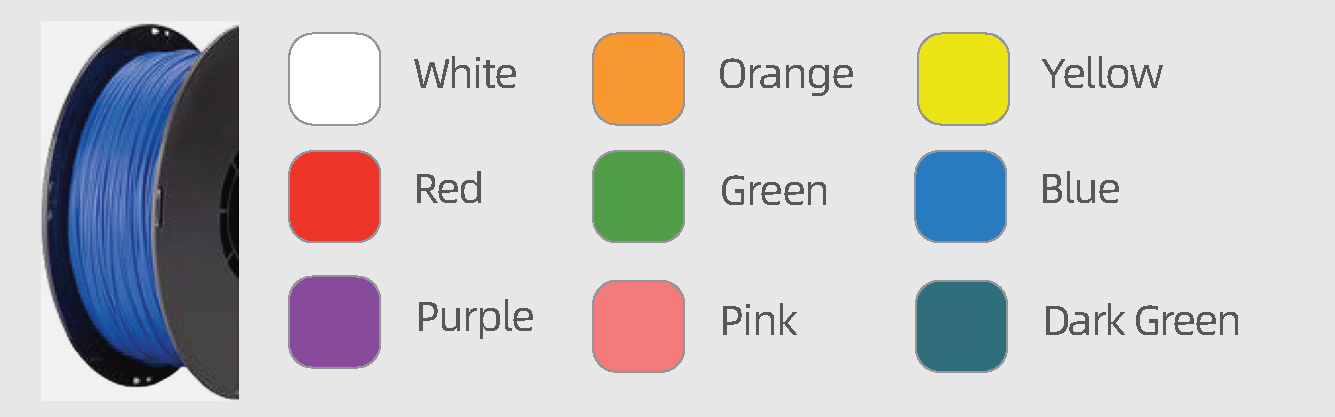

SoliFuse has developed a dedicated solution for 3D printing as a true alternative to traditional signage methods. The SoliFuse Speed Series 3D printers are industrial-grade machines purpose-built for making channel letters, combining large build volumes, dual-extrusion technology, and fast print speeds to meet the needs of signage fabrication.