Metal Laser Cutting Machines — Complete Guide to Cutting, Welding & Cleaning Metal

When people ask me about metal laser cutting machines, I always say the same thing:

A metal laser cutter can change your business, your workshop, and even your income.

I’ve been in the laser industry for years, and at Max Laser, I help people start and grow real businesses using laser machines — from signage, fabrication, engineering, décor, metalworking, and even side-hustles from home. So I decided to put together a complete, easy-to-understand guide for anyone looking for a metal laser cutting machine in South Africa.

On this page, I break everything down in a natural, simple way:

- What a metal laser cutting machine actually is

- What you can cut

- Who uses these machines

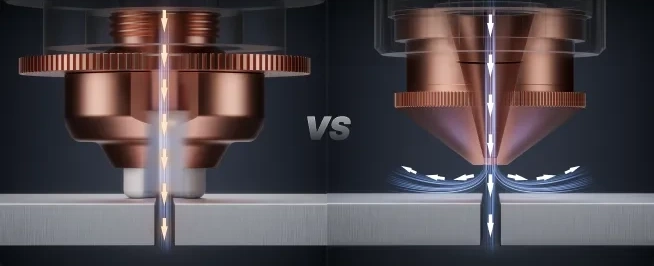

- How fiber laser technology works

- Why a metal laser cutter is better than plasma or CNC routing

- How the XTool Metal Fab (3-in-1 Cutting + Welding + Cleaning Fiber Laser) works

- Business ideas you can start with metal cutting, welding and cleaning

- My honest advice from years in the laser industry

- And a complete FAQ with deep, detailed answers

I’ll also show you exactly where this machine fits into your business — whether you’re a small workshop, starting a side hustle, or running a full fabrication company.

Let’s get into it.