Heat Press Machines

Best Heat Press Machines 2024

In South Africa, it’s common to know someone—be it a family member, cousin, or friend—running a profitable heat press business. This may have inspired you to consider starting your own venture. If you’re wondering which machine to invest in, you’ve come to the right place.

Cheap Heat Press Machines

Many opt for the cheapest machine available as a starting point, thinking it’s a low-risk way to enter the business. However, before you make a purchase, I recommend saving a bit longer to invest in the right machine that truly suits your business needs.

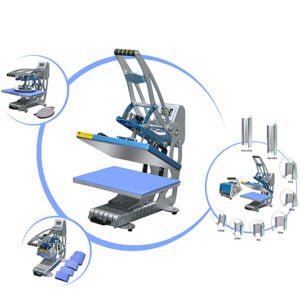

Types of Heat Press Machines

To guide your decision, here’s a breakdown of the main types of heat press machines:

- Pneumatic Heat Press: Utilizes air pressure for uniform pressure distribution.

- Clamshell Heat Press: Opens and closes like a clamshell, ideal for beginners.

- Swing Away Heat Press: Swings the heat platen away, allowing more layout space.

- Draw Heat Press: Features a drawer design for layout adjustments without heat risk.

- Mug Heat Press: Specialized for transferring designs onto cylindrical mugs.

- Cap Heat Press: Designed specifically for hats, caps, and other headwear.

- Flat Bed Heat Press: Suitable for various flat surface items.

- 16 in 1 Heat Press Machine: A versatile option that can handle multiple applications.

It’s tempting to go for the least expensive option, but it’s important to be aware of the pitfalls associated with cheaper machines.

Although initially appearing cost-effective, opting for the least expensive equipment often leads to greater long-term expenses and challenges.

Here’s why investing in a low-cost model might not be the best decision for your business:

- Durability and Reliability Issues: Cheaper heat press machines tend to be made with lower-quality materials and components. This can lead to frequent breakdowns and the need for repairs or replacements sooner than expected. The durability of a heat press is crucial, as consistent performance is key to maintaining production schedules and meeting customer demands.

- Inconsistent Heat Distribution: One of the most critical features of a heat press is its ability to distribute heat evenly across the platen. Cheaper models often struggle with maintaining uniform heat, which can result in unevenly pressed products and a high rate of defects. This not only wastes materials but can also damage your reputation if poor-quality products reach your customers.

- Higher Operational Costs: Inefficiencies in energy use and prolonged pressing times due to inadequate temperature controls in cheaper machines can lead to increased electricity costs. Over time, these increased operational costs can significantly impact your profitability.

- Safety Concerns: Lower-cost machines might not meet high safety standards or come equipped with essential safety features, such as emergency stop buttons or proper insulation. This could pose risks to you and your employees, leading to potential accidents and liability issues.

Key Features to Consider in Quality Heat Press Machines

When I first ventured into the heat press industry, understanding all the features of these machines was a huge learning curve but important for ensuring I made a wise investment.

Let me walk you through some of the key features you should consider when selecting a quality heat press machine.

- Even Heat Distribution: It’s crucial for a heat press to evenly spread heat across its surface. This consistency helps ensure that every part of your design transfers correctly, avoiding defective products. From my experience, reliable, even heating is essential for professional-quality results.

- Adjustable Pressure Settings: Different products and transfer materials require different amounts of pressure. A quality heat press allows you to adjust the pressure according to the substrate you are working with. Whether you’re pressing a thick hoodie or a delicate tee, being able to control the pressure ensures that you don’t damage the material or the design. It’s a feature that adds versatility to your operations, allowing you to work with a wide range of materials and thicknesses.

- Digital Controls and Timers: Precision is key in heat pressing. Digital controls and timers play a pivotal role in ensuring that you can replicate perfect results every time. These features allow you to set exact temperatures and pressing times, reducing the chances of human error.

In my practice, I’ve found that digital controls not only make the machine easier to use but also significantly enhance the repeatability of the pressing process. This is particularly important when you are fulfilling large orders where consistency across all items is crucial.

Investing in a heat press with these essential features has profoundly impacted the quality and efficiency of my projects. They may come at a premium, but the improvement in product quality and the reduction in waste will quickly offset the initial higher cost.

Remember, in a business where the finish of the product is everything, compromising on these features can cost you more than just money—it can impact your brand’s reputation.

The Best Heat Press Machines For Your Business

Let’s take a closer look at each type of heat press machine and understand what each is best suited for, along with their respective pros and cons.

Pneumatic Heat Press

- Best For: High-volume, professional environments where consistency and efficiency are key.

- Pros: Automatic pressure application reduces operator fatigue.Consistent pressure ensures high-quality results across large batches.

- Cons: Higher cost compared to other types. Requires access to compressed air, which may not be available in all settings.

Clamshell Heat Press

- Best For: Small businesses and beginners needing a straightforward, space-saving solution.

- Pros: Compact design saves workspace. Simple to operate, making it ideal for beginners.

- Cons: Limited layout space can restrict the types of products you can work on. Heat distribution near the hinge might be inconsistent.

Swing Away Heat Press

- Best For: Businesses that require precise placement and safer operation for a variety of products.

- Pros: Full access to the work area allows for precise layout without interference from the heat platen. Safer to operate as the heat is moved away during layout adjustments.

- Cons: Requires more operating space, which may not suit smaller workshops.

Draw Heat Press

- Best For: Environments where operator safety and ease of use are prioritized.

- Pros: Drawer design minimizes risk of burns, enhancing operator safety. Allows for easy adjustment of materials and layouts.

- Cons: Needs extra frontal space for the drawer, which could be a constraint in tight spaces.

Mug Heat Press

- Best For: Specialized businesses focused on custom drinkware like mugs and bottles.

- Pros: Ideal for high-quality prints on cylindrical surfaces. Expands product offerings with custom drinkware.

- Cons: Limited to cylindrical items, reducing versatility.

Cap Heat Press

- Best For: Companies specializing in custom headwear and promotional caps.

- Pros: Contoured platen fits caps and hats perfectly, ensuring quality prints. Great for adding value to branded merchandise lines.

- Cons: Not suitable for flat or larger items, limiting its use to only headwear.

Flat Bed Heat Press

- Best For: Versatile applications across a wide range of flat items, from apparel to decorative pieces.

- Pros: Highly versatile, suitable for a broad array of products. Simple design is easy to use for operators of all skill levels.

- Cons: Not suitable for items with raised or recessed areas.

16 in 1 Heat Press Machine

- Best For: Businesses looking to maximize versatility and offer a wide range of customized products.

- Pros: Multiple attachments enable production of t-shirts, mugs, hats, and more with one machine. High versatility makes it a cost-effective solution for expanding product lines.

- Cons: Higher initial investment and potentially complex setup. Larger footprint required for storage and operation.

When I started to distribute heat press machines, like many new entrepreneurs, I faced a significant learning curve. Choosing the right equipment was one of my earliest and most crucial decisions.

Unfortunately, my initial choice wasn’t well-aligned with my business needs, leading to inefficiencies and, ultimately, financial losses that wiped out some capital.

This experience taught me the importance of evaluating my business needs before investing in new equipment. Here’s a simplified guide based on what I learned from that experience.

Evaluating Your Business Needs Before Investing

Understanding the volume of orders you expect to handle is crucial. When I first began, I underestimated the volume, leading to delays and dissatisfied customers when my equipment couldn’t keep up.

Consider whether you’ll be doing small, custom batches or large-scale productions. This decision will significantly influence the type of heat press machine that best fits your operations.

Factors to Consider

- Volume of Orders: Assess how many items you plan to produce in a given time frame. Will your machine need to operate all day, or just for a few hours? High-volume orders will require a more robust, possibly automated machine.

- Variety of Products: Initially, I didn’t consider the range of products I wanted to offer. A versatile machine, like a 16 in 1 heat press, might be ideal if you plan to expand your product line to include items like t-shirts, mugs, and hats.

- Space Considerations: Ensure you have enough space for the machine you choose, especially if you opt for a model with a larger footprint like a swing-away heat press.

Aligning Machine Choice with Business Goals

Choosing the right machine is about more than just the current needs; it’s about your future goals too. After losing my initial investment, I had to start saving again, this time with a clearer strategy.

I needed to offer machines that not only met my client’s production needs but also offered room for growth. For instance, investing in a slightly more expensive but highly versatile machine can prevent the need for future upgrades as your business expands.

Conclusion

In conclusion, finding the right heat press machine is essential for anyone looking to excel in the competitive market of customized products. This article has highlighted the top models available, from versatile multi-functional units to robust pneumatic presses, each designed to meet various business demands.

Choosing a heat press should be a strategic decision, not just based on price but on quality and suitability for your operations. A reliable machine minimizes downtime and ensures consistent product quality, thereby enhancing your brand’s reputation and market presence.

Before finalizing your purchase, carefully consider your production volume, the diversity of products you plan to create, and the workspace you have. These factors will help you select a machine that not only meets your current needs but also supports future business growth.

For personalized advice on selecting the best heat press machine, feel free to reach out. Let us help you secure the equipment that your business needs to thrive.