Laser Cutting MDF Board: A Practical Guide to Clean Cuts, Engraving Quality & Profitable Products

Laser cutting MDF board is one of the most common starting points for anyone entering the laser cutting and engraving space. MDF is affordable, widely available in South Africa, easy to work with, and versatile enough to produce everything from signage and décor to craft products and branded items.

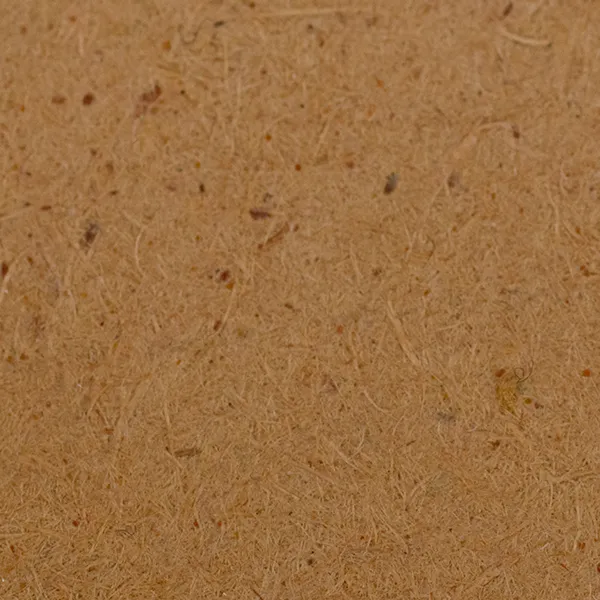

However, not all MDF behaves the same on a laser machine. Differences in composition, thickness, glue content, and surface finish can dramatically affect cut quality, engraving contrast, edge cleanliness, and even safety.

This guide is written from real workshop experience. It is designed to help beginners and small business owners understand how MDF actually behaves when laser cut or engraved, so you can choose the right material, settings, and machine for consistent, profitable results.